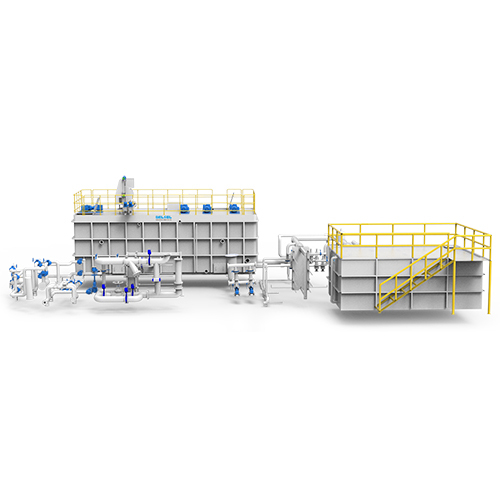

Roll Coolant Filtration System

Price 2500000.00 INR/ Unit

Roll Coolant Filtration System Specification

- Product Type

- Other

- Material

- Aluminum alloys

- Inlet/Outlet

- LPM

- Size

- Different Sizes Available

Roll Coolant Filtration System Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 12 Units Per Year

- Delivery Time

- 1 Months

- Main Domestic Market

- All India

About Roll Coolant Filtration System

Our Roll Coolant Filtration System is a specialized filtration unit used in metal rolling mills (especially steel and aluminium processing) to filter and recirculate the coolant used in the rolling process. These systems play a critical role in maintaining the quality of the rolled product, protecting equipment, and extending coolant life.

WHAT IS A ROLL COOLANT FILTRATION SYSTEM?

Its an industrial filtration setup designed to:

- Clean and recycle coolant (oil or emulsion) used in rolling mills.

- Remove contaminants such as metal fines, scale, and debris.

- Maintain fluid temperature, pressure, and cleanliness to ensure efficient rolling operations.

WHY IS FILTRATION IMPORTANT IN ROLLING MILLS?

- Improves surface finish of the rolled material.

- Reduces tool and roll wear.

- Minimizes downtime due to maintenance.

- Increases coolant lifespan and reduces disposal costs.

- Prevents clogging and wear of downstream equipment (like heat exchangers, pumps, etc.).

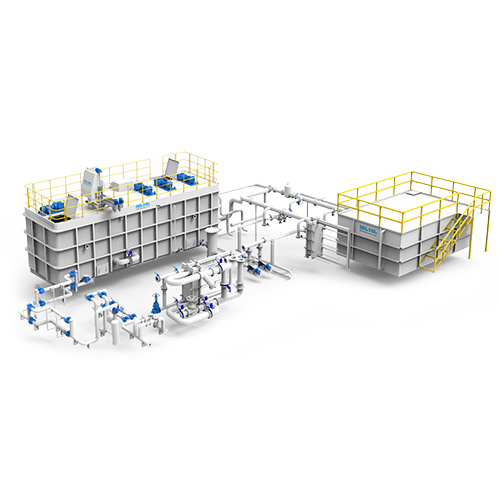

SYSTEM COMPONENTS

- Collection Troughs / Tanks: Collect coolant from mill stand area.

- Coarse Pre-Filters: Remove large particles, scale, and chips.

Main Filtration Units

May include:

- Vertical Type Candle Magnetic Separator

- Agitator

- Self-cleaning filtration system

- Oil Skimmer

- Compact band filter

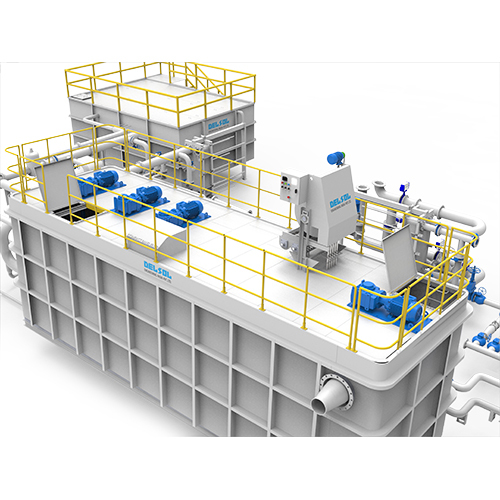

Clean Coolant Tank: Stores filtered coolant ready for reuse.

Pump Systems: Transfer coolant through the system and back to the mill.

Cooling Units (Optional): Heat exchangers or chillers to maintain coolant temperature.

Control Panel (PLC / HMI): Manages operations, alarms, and monitoring.

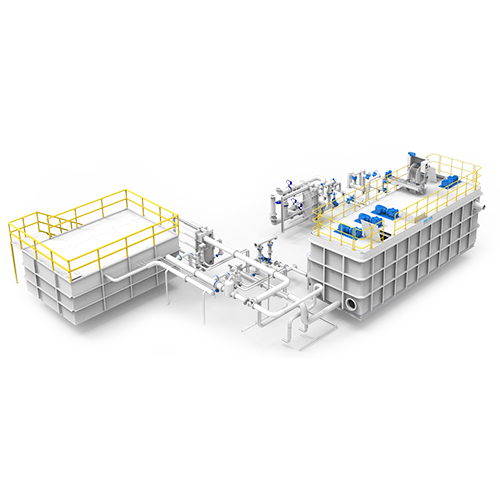

WORKING PRINCIPLE (GENERAL FLOW)

- Dirty coolant from the rolling mill is collected.

- Coarse filtration removes large debris.

- It passes through fine filtration (Compact band filter / Self-cleaning filter / Vertical Type Candle Magnetic Separator / Oil Skimmer)

Clean coolant is cooled (if required).

Coolant is pumped back to the rolling process.

Sludge/particles are collected and disposed of or processed.

COOLANT TYPES

- Water-based emulsions (common in aluminium mills)

- Oil-based coolants (used in cold rolling of steel)

- Synthetic or semi-synthetic fluids

APPLICATIONS

- Steel cold rolling mills

- Aluminium strip mills

- Tandem rolling lines

- Hot/cold rolling stands

- Pickling & finishing lines

DESIGN CONSIDERATIONS

- Flow rate (m/hr or LPM)

- Filtration accuracy (micron rating)

- Type and concentration of contaminants

- Type of coolant fluid

- Required temperature control

- Footprint and layout

- Automation and monitoring level

ADVANTAGES

- Improves product quality

- Reduces operational costs

- Environmentally friendly (reduced disposal)

- Ensures equipment longevity

- Consistent rolling process

GENERAL INFORMATION

- Manufacturer: Delsol Engineering India Pvt Ltd.

- Model: RCFS-Series (customizable as per application)

- Application: Coolant filtration for steel/aluminium rolling mills

TECHNICAL SPECIFICATIONS

| Parameter | Specification | ||

| Flow Capacity | 50 to 1000 m/hr | ||

| Filtration Accuracy | 10 - 50 microns | ||

| Coolant Type | Water-based / Oil-based | ||

| System Type | Modular / Skid-mounted / Central | ||

| Main Filtration Technology | Compact band filter / Self-cleaning filter / Vertical Type Candle Magnetic Separator / Oil Skimmer | ||

| Clean Coolant Tank Capacity | As per customized design | ||

| Pump Type | Centrifugal | ||

| Cooling System (optional) | Plate Heat Exchanger / Chiller | ||

| Construction Material | MS / SS 304 | ||

| Electrical Panel | PLC-based | ||

| Power Supply | 415V, 50Hz, 3-Phase | ||

| | | | |

PERFORMANCE

- Designed for 24/7 industrial operation

- Recycles up to 95% of coolant

- Maintains coolant clarity and temperature

INSTALLATION REQUIREMENTS

- Space: As per layout drawing

- Utility Requirements:

- Electrical: 415V, 50Hz

- Water (for cooling if applicable)

- Drainage connection

OPTIONAL FEATURES

- SCADA Integration

- Sludge Dewatering System

- Remote Monitoring

DOCUMENTATION PROVIDED

- GA Drawings

- PFD (Proses flow Diagram)

- P&ID (Piping And Instrumentation Diagram)

- Test Certificates

- User Manual

- Electrical Wiring Diagram

WARRANTY & SUPPORT

- Warranty: 12 months from date of commissioning

- On-site support & AMC available

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Roll Coolant System Category

ROLL COOLENT FILTERATION SYSTEM

Price 2500000 INR / Unit

Minimum Order Quantity : 1 Unit

Inlet/Outlet : LPM

Product Type : Other

Material : MS

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese