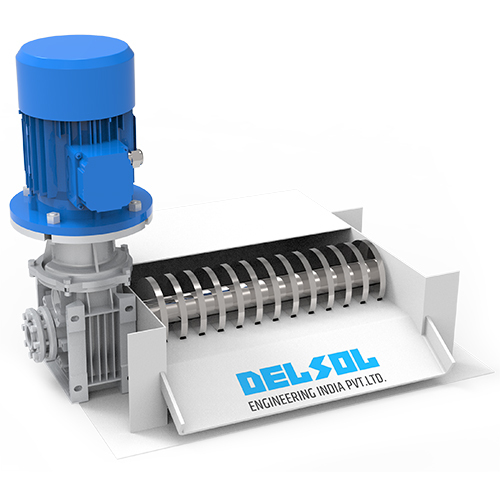

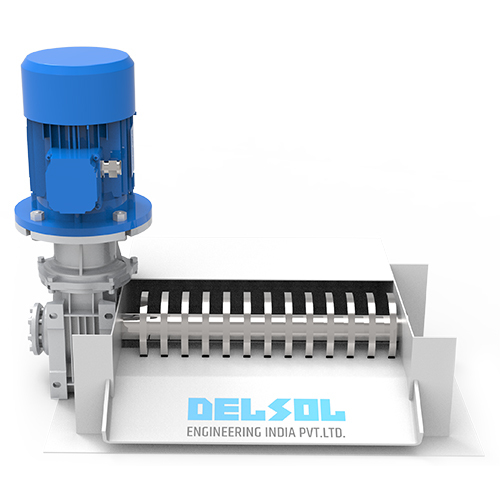

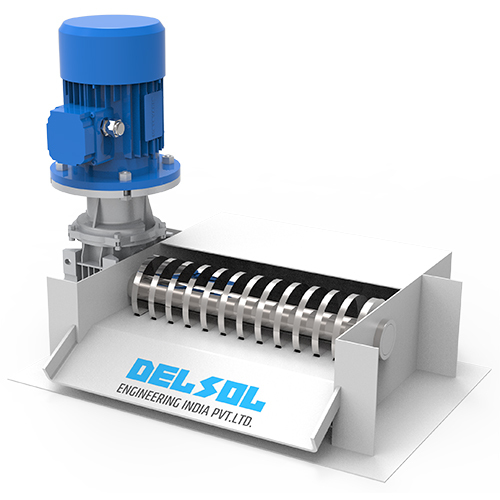

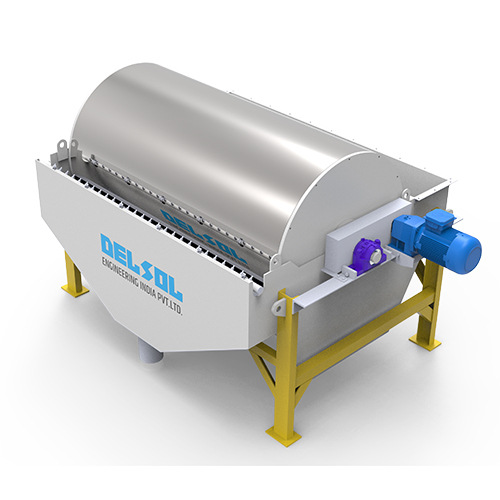

Magnetic Separator

Price 35000 INR/ Unit

Magnetic Separator Specification

- Power

- 440 Volt (v)

- Voltage

- 440 Volt (v)

- Frequency

- 50 Hertz (HZ)

- Power Supply

- 3 Phase

- Product Type

- Magnets

- Magnet Type

- Ferrite Magnet

- Weight

- 50 To 300 Kilograms (kg)

Magnetic Separator Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 30 Units Per Month

- Delivery Time

- 15 Days

- Main Domestic Market

- All India

About Magnetic Separator

ïWhat is a Magnetic Separator?

A Magnetic Separator is a filtration device used to remove ferrous particles (iron, steel, etc.) from process fluids such as coolant, oil, or emulsions. It works by attracting ferromagnetic contaminants using strong magnets, improving fluid quality and protecting downstream equipment.

TYPES OF MAGNETIC SEPARATORS

- Drum Type Magnetic SeparatorRotating drum with permanent magnetsCommon in coolant filtration systems

- Roller Type Magnetic SeparatorMultiple rotating rollers for high-efficiency separationSuited for high-contamination environments

- Candle Type Magnetic SeparatorVertical or horizontal housing with magnetic rodsCompact design for finer filtration

- Overband Magnetic SeparatorMounted over conveyors to remove ferrous tramp

- Drawer or Grill TypeManual cleaning, used in dry bulk materials

CONSTRUCTION & WORKING (Drum Type as example)

Components:

- Magnetic drum (rotating)

- Housing with inlet and outlet

- Scraper blade

- Coolant tank integration

- Optional gear motor

ïWorking Principle:

- Contaminated fluid enters the magnetic separator.

- Ferrous particles are attracted to the rotating drum surface.

- As the drum rotates, clean fluid flows out.

- A scraper removes ferrous sludge from the drum into a sludge box.

TECHNICAL SPECIFICATIONS (Typical)

| Parameter | Range |

| Flow Rate | 30ï 1000 LPM |

| Magnetic Strength | Up to 6000 Gauss |

| Drum Diameter | 150ï 400 mm |

| Material of Construction | MS / SS |

| Cleaning Type | Manual / Semi-Automatic |

| Mounting | Standalone or on filtration unit |

APPLICATIONS

- Grinding (surface, cylindrical, centerless)

- Honing, turning, milling

- EDM and wire-cut machines

- Cast iron machining

- Steel and aluminum operations

ADVANTAGES

ï

- Maintenance-free operation

- No consumables like paper media

- Increases coolant life

- Compact & cost-effective

- Environment-friendly

- Enhances tool life & surface finish

ï

ADVANCED FEATURES (Optional)

- Rare-earth magnets (for high-performance)

- Motorized drum

- Flow control bypass

- Integration with Paper Band or Compact Band Filter

- PLC control with auto sludge removal

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese