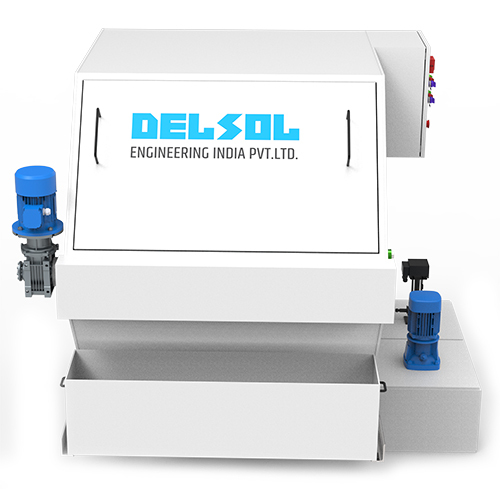

Compact Band Filter

Price 125000 INR/ Unit

Compact Band Filter Specification

- Usage

- Industrial Oil Filtration

- Type

- Machine Oil Filter

- Height

- 1000 To 2200 Millimeter (mm)

- Product Type

- compact band filtration system

- Automation

- Automatic

- Color

- RAL 7035, Appel Green

- Width

- 1000 To 1250 Millimeter (mm)

- Voltage

- 440 Volt (v)

- Length

- 1000 To 2000 Millimeter (mm)

- Weight

- 600 To 2200 Kilograms (kg)

- Warranty

- 1 Years

Compact Band Filter Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 1 Months

- Main Domestic Market

- All India

About Compact Band Filter

ïWhat is a Compact Band Filter?

A Compact Band Filter is an automatic gravity-type coolant filtration unit designed to filter fine and coarse particles from liquids like cutting fluids, grinding coolants, and other process fluids. It uses filter media (filter paper) that automatically advances as it clogs, ensuring uninterrupted filtration.

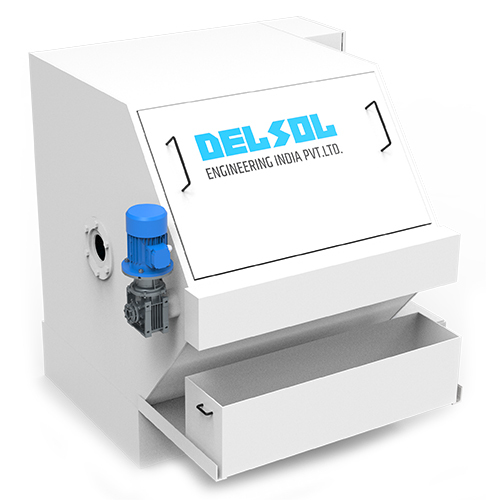

CONSTRUCTION & WORKING

ïMain Components:

- Inlet Chamber: Receives dirty coolant.

- Filter Bed: Supports the filter media roll.

- Filter Media (Paper Roll): The disposable paper removes contaminants.

- Clean Tank: Stores filtered coolant.

- Float Switch / Level Controller: Senses clogging and triggers media advancement.

- Drive Motor / Gear Mechanism: Moves the filter media forward when clogged.

ïWorking Principle:

- Dirty coolant enters the inlet.

- Coolant passes through filter paper solid particles are retained.

- Clean coolant is collected below and reused.

- When the filter paper gets clogged, the float switch activates the motor.

- Used media is rolled up, and fresh paper is unrolled.

TECHNICAL SPECIFICATIONS (Typical Ranges)

| Parameter | Range |

| Flow Capacity | 30ï 1000 LPM (or more) |

| Filtration Accuracy | 20ï 50 microns (depends on media) |

| Filter Media Width | 300 1000 mm |

| Construction Material | MS / SS 304 / SS 316 |

| Power Supply | 230V/415V AC |

| Filter Paper Material | Non-woven polyester cellulose |

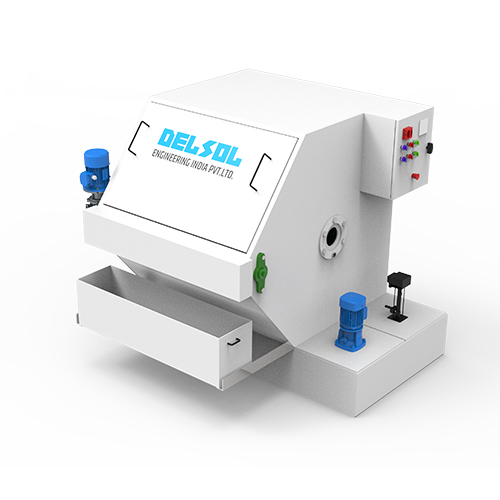

TYPES OF FILTER MEDIA

- Cellulose-based paperïstandard for general metalworking fluids

- Polyester-based non-wovenï high strength and chemical resistance

- Needle punchedï for sticky/slurry applications

APPLICATIONS

- Grinding machines (surface, cylindrical, centerless)

- Honing and lapping operations

- Milling, turning & drilling

- Washing machines

- Cast iron, aluminum, and brass machining

ADVANTAGES

ï

- Fully automatic

- Compact footprint

- Cost-effective operation

- Easy maintenance

- Customizable for various flow rates

- Better tool life & surface finish due to clean coolant

ï

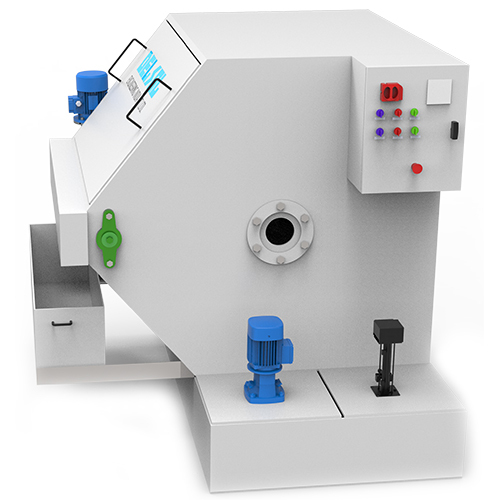

ADVANCED OPTIONS

Optional Add-ons:

- Magnetic separator attachment (for ferrous contaminants)

- Chiller unit for temperature control

- Sludge scrapers

- Paper roll status sensors

- Level switches with PLC control

- Integrated pump-back systems

Custom Configurations:

- Duplex filters

- SS304/316 construction for chemical-resistant applications

- Larger capacity tanks

- Pressure-assisted models for difficult filtration

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese