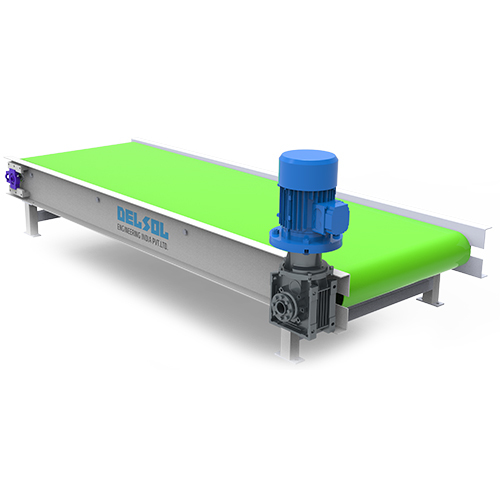

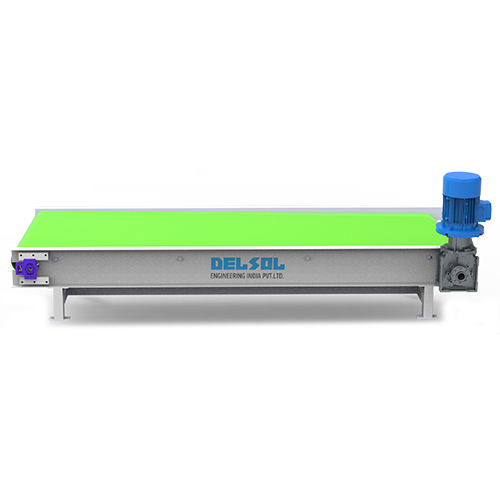

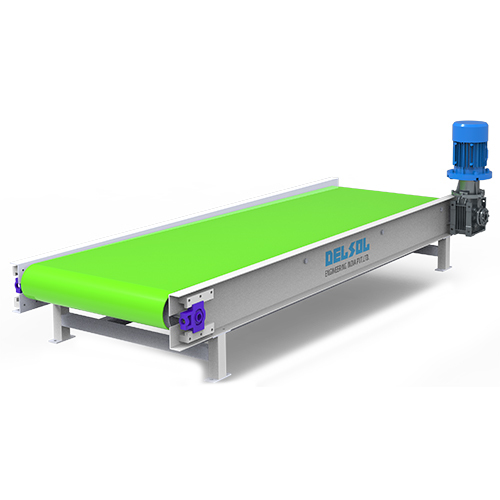

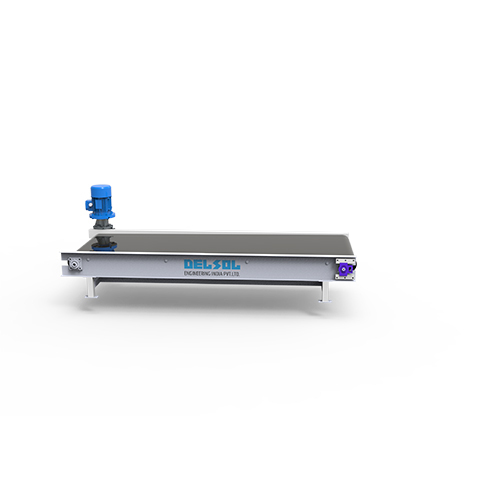

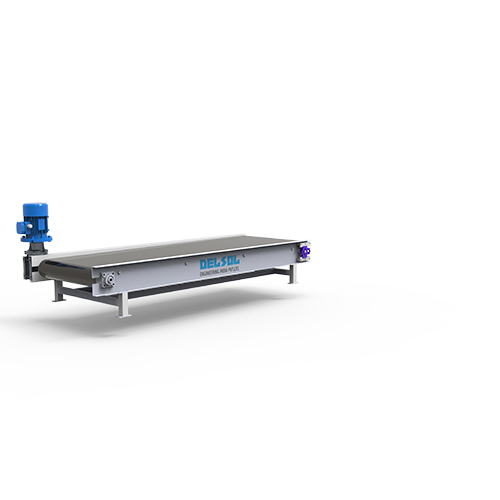

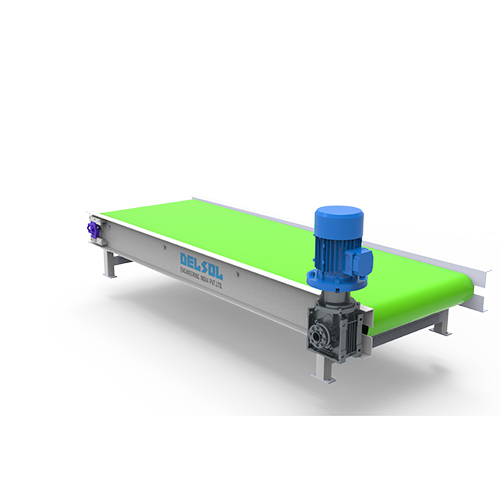

Belt Conveyors

Price 25000 INR/ Unit

Belt Conveyors Specification

- Power Source

- 440

- Thickness

- 3 to 5 Micrometers (um)

- Usage

- Industrial

- Material

- MS & SS

- Type

- Belt Conveyor

- Height

- 300 To 3600 Millimeter (mm)

- Structure

- Belt

- Product Type

- Conveyor

- Belt Conveyor

- Flat Belt

- Weight

- 50 To 3500 Kilograms (kg)

- Color

- RAL 7035, Black, Appel Green

- Length

- 1000 To 15000 Millimeter (mm)

- Width

- 300 To 1800 Millimeter (mm)

- Load Capacity

- 10 to 5000 Kilograms (kg)

- Voltage

- 440 Volt (v)

- Power

- 440 Volt (v)

- Speed

- 10 To 100 RPM

- Warranty

- 1 Years

Belt Conveyors Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 25 Units Per Month

- Delivery Time

- 15 Days

- Main Domestic Market

- All India

About Belt Conveyors

ïWHAT IS A BELT CONVEYOR?

A Belt Conveyor is a mechanical material handling system that uses a continuous belt loop to transport bulk or unit materials over a horizontal or inclined path. It is widely used in industries for efficient, fast, and safe transfer of material.

WORKING PRINCIPLE

- A continuous belt is stretched over two or more pulleys (driven and idle).

- One pulley (drive pulley) is powered by a motor, moving the belt forward.

- The belt carries the material along the conveying path.

- The material is loaded at the inlet and discharged at the outlet via gravity or scraper.

TYPES OF BELT CONVEYORS

| Type | Description | Use Case |

| Flat Belt Conveyor | Simple horizontal transport of unit goods | Assembly lines, packing stations |

| Inclined/Declined Conveyor | Transports material at angles | Loading/unloading, bins |

| Cleated Belt Conveyor | Belt has raised cleats to carry materials uphill | Chips, grains, granules |

| Trough Belt Conveyor | Belt edges are curled to form a trough | Bulk solids (coal, sand, ores) |

| Modular/Plastic Belt Conveyor | Belt made of plastic links | Food, pharma, clean room |

| Heavy-Duty Belt Conveyor | Designed for large loads, harsh conditions | Mining, cement, steel plants |

TECHNICAL SPECIFICATIONS

| Parameter | Typical Range |

| Belt Width | 100 mm to 2000 mm |

| Conveyor Length | 0.5 m to 100+ m |

| Belt Speed | 0.1 m/s to 3 m/s |

| Capacity | 10 kg/hr to 1000 TPH |

| Belt Material | Rubber, PVC, PU, Nylon, Steel Cord, Modular |

| Frame Material | MS, SS304, SS316, Aluminium |

| Motor Power | 0.5 HP to 15 HP |

| Drive Type | Direct, geared, pulley, drum motor |

| Inclination Angle | 0 to 35 (depends on belt & material) |

| Support Rollers | Impact, troughing, return, training |

APPLICATIONS

Manufacturing & Assembly:

- Moving boxes, components, cartons

- Packaging and inspection lines

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese