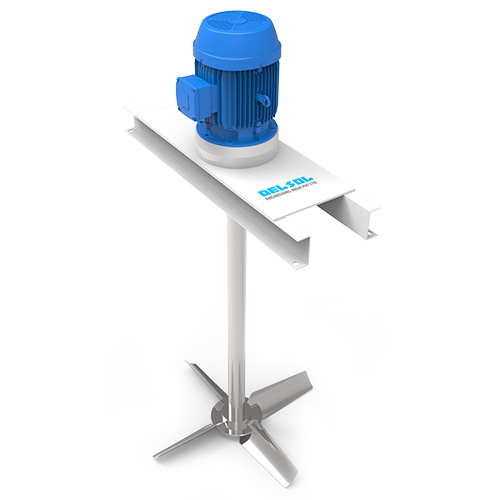

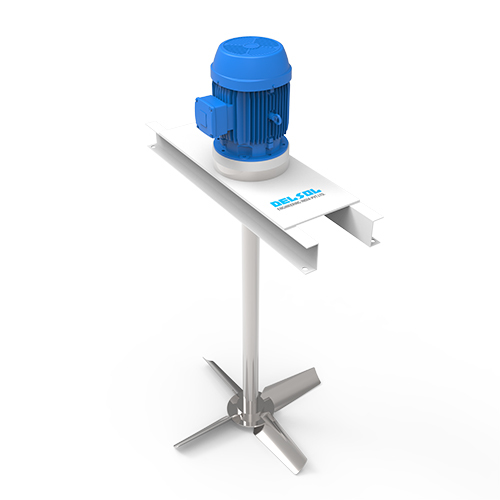

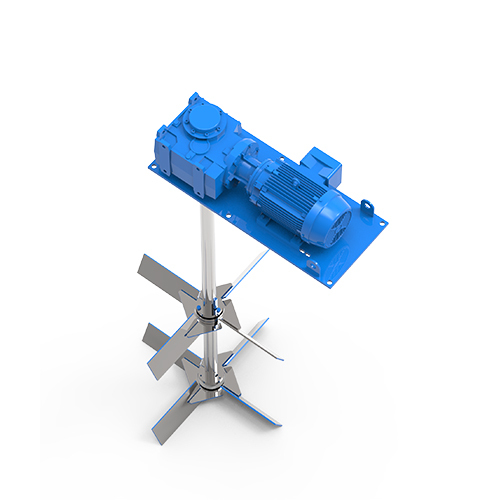

Industrial Agitator

Price 25000 INR/ Unit

Industrial Agitator Specification

- Condition

- New

- Max. Lifting Height

- 2800 Millimeter (mm)

- Power Source

- Electric

- Power Consumption

- 440 Volt (V)

- Voltage

- 440 Volt (v)

- Length of Belt

- 350 To 1800 Millimeter (mm)

- Warranty

- 1 Years

- Attributes

- Strong, Durable, Easy To Operate, Rust Proof, Consume Less Power

Industrial Agitator Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 15 Units Per Month

- Delivery Time

- 1 Months

- Main Domestic Market

- All India

About Industrial Agitator

THE INDUSTRIAL AGITATOR!

WHAT IS AN INDUSTRIAL AGITATOR?

An industrial agitator is a mechanical device usedfor mixing, blending, or maintaining uniformity of materials (liquid orslurry) in tanks. Its widely used in industries like chemicals,pharmaceuticals, food processing, water treatment, and paints.

WORKING PRINCIPLE

An industrial agitator works by rotating an impeller orblade inside a tank or vessel. The rotation creates fluid flow,which promotes:

- Homogeneous mixing

- Heat or mass transfer

- Suspension of solids

- Emulsification or dispersion

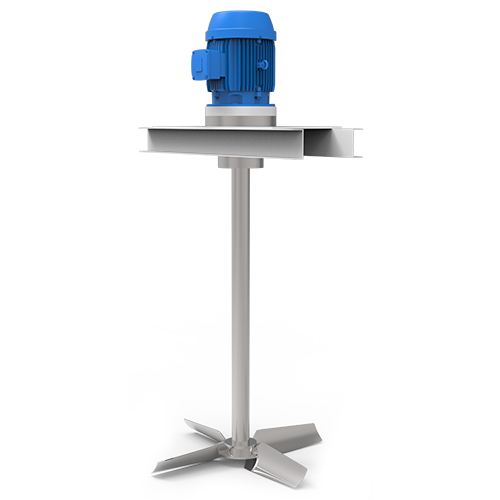

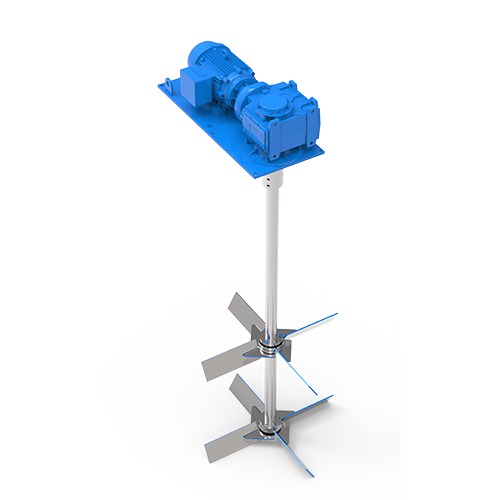

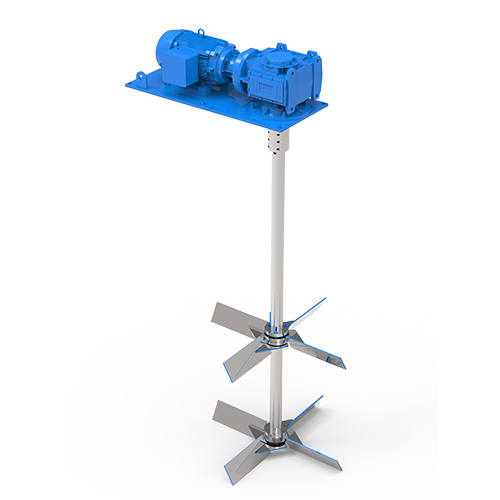

CONSTRUCTION &MAIN COMPONENTS

- Motor: Provides power to the shaft.

- Gearbox: Reduces speed and increases torque.

- Mounting System: Top, bottom, or side-mounted.

- Agitator Shaft: Connects the motor to the impeller.

- Impeller/Blade: The mixing element.

- Sealing system: Mechanical seal or stuffing box to prevent leakage.

TYPES OF INDUSTRIAL AGITATORS

Based on Mounting:

| Type | Description |

| Top Entry Agitator | Mounted on the top of the tank, ideal for large tanks. |

| Side Entry Agitator | Used for storage tanks with limited height. |

| Bottom Entry Agitator | Installed at the tank bottom, often for sanitary applications. |

Based on Agitator Design:

| Type | Application |

| Turbine Agitator | High shear mixing, gas-liquid dispersion |

| Propeller Agitator | Low-viscosity fluids |

| Paddle Agitator | Viscous fluids, gentle mixing |

| Anchor Agitator | High-viscosity mixing (paints, gels) |

| Helical Agitator | Pseudoplastic fluids |

|

|

|

AGITATOR SELECTIONCRITERIA

When choosing an agitator, consider:

| Factor | Description |

| Tank Volume | Determines power and impeller size |

| Viscosity of Fluid | Impacts type of impeller |

| Mixing Purpose | Blending, heat transfer, suspension, etc. |

| Speed (RPM) | High speed for low viscosity, low speed for high viscosity |

| Material of Construction | SS304, SS316, Hastelloy, etc., depending on media |

| Mounting Requirements | Depends on tank design |

STANDARD DESIGNFEATURES

- Capacity in HP: 0.5 Hp to 20 Hp.

- Capacity in litre: 50 liters to 2,00,000+ liters

- Speed: 10 to 300 RPM

- Shaft length: Customizable

- Materials: SS304, SS316L, Duplex steel

- Surface finish: Mirror polish, electro-polish for pharma

INDUSTRIAL APPLICATIONS

| Industry Oil industry | Use Case Mixing coolant oil, adessive, sludge |

| Chemical | Mixing of resins, acids, and solvents |

| Pharmaceutical | Emulsification, suspension, sterile mixing |

| Food & Beverage | Syrups, juices, sauces |

| Paint & Coatings | Pigment dispersion |

| Water Treatment | Flocculation, pH adjustment |

| Pulp & Paper | Pulp slurries, dye mixing |

ADVANTAGES

- High mixing efficiency

- Uniform product quality

- Energy-efficient designs

- Customizable for any application

- Scalable for batch or continuous process

DOCUMENTS FORINDUSTRIAL USE

- General Arrangement Drawing (GAD)

- Datasheet with motor HP, RPM, shaft details

- Material test certificate (MTC)

- FAT (Factory Acceptance Test) report

- User manual & installation guideline

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese