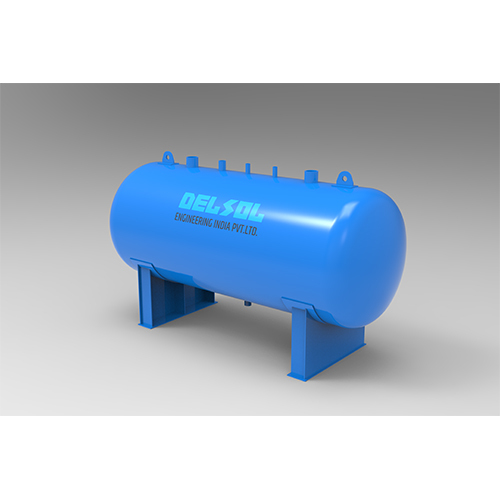

Industrial Air Receiver Vessel

Price 50000 INR/ Unit

Industrial Air Receiver Vessel Specification

- Usage

- Industrial

- Material

- MS & SS

- Size

- Different available

- Capacity

- 50 To 5000 Ltr

- Height

- 300 To 3800 Millimeter (mm)

- Product Type

- Reservoir & Vessel

- Condition

- New

- Weight

- 300 To 3000 Kilograms (kg)

- Color

- Silver, Gray, Blue, Appel Green.

- Width

- 300 To 2200 Millimeter (mm)

Industrial Air Receiver Vessel Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 30 Days

- Main Domestic Market

- All India

About Industrial Air Receiver Vessel

Air Reservoir Complete Information

What is an AirReservoir?

An air reservoir, also known as an airreceiver tank, is a pressure vessel used to store compressed air before itenters the piping system or air-consuming devices. It helps in maintaining consistentair pressure, reduces compressor cycling, and acts as a buffer during peakdemand.

Function andBenefits

Stores compressed air for future use

Reduces pressure fluctuations

Dampens pulsations from reciprocating compressors

Acts as a heat exchanger (air cools down before use)

Helps remove moisture and oil droplets

Reduces compressor wear by minimizing load/unload cycles

Types of AirReservoirs

Vertical Air Reservoir Saves floorspace, commonly used indoors.

Horizontal Air Reservoir Easier access for maintenance, used where heightis restricted.

Mobile/Portable Reservoir Mounted on wheels for mobile applications.

TypicalSpecifications (Example: 0.8 m Vertical Type)

Capacity: 0.8 cubic meters

Orientation: Vertical cylindrical

Construction: Welded steel plate

Design Pressure: 10 bar (typical)

Test Pressure: 1.5 design pressure (e.g., 15 bar)

Certification: ASME Section VIII Div. 1 or IS:2825

Connections: Inlet, outlet, drain, safety valve, pressure gauge

Surface Finish: Red oxide primer + enamel coat or galvanization

Materials Used

Shell & Heads: Carbon steel orstainless steel

Nozzles & Fittings: Carbon steel, SS, or brass

Coating: Internal anti-corrosion epoxy or food-grade coating if required

Applications

Compressed air systems in factories

Pneumatic automation lines

Air brakes in locomotives and heavyvehicles

HVAC systems and air dryers

Energy storage and buffering in peak load

Design Standards & Testing

Design Code: ASME Section VIII Div. 1 orIS 2825

Hydrostatic Test: As per ASME UG-99 (usually 1.3 to 1.5 times designpressure)

Non-Destructive Testing (NDT): Radiography, ultrasonic, or dye penetranttesting

Safety Accessories: Pressure relief valve, drain valve, pressure gauge

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese