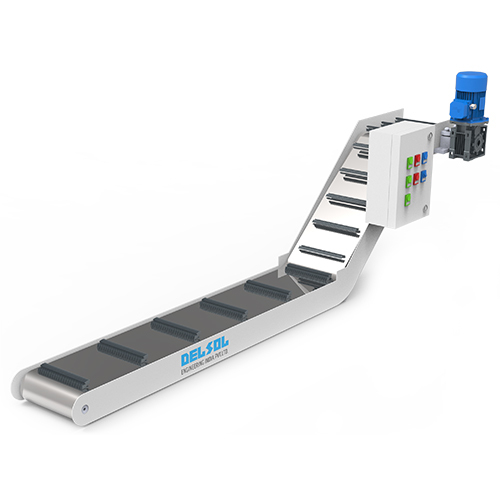

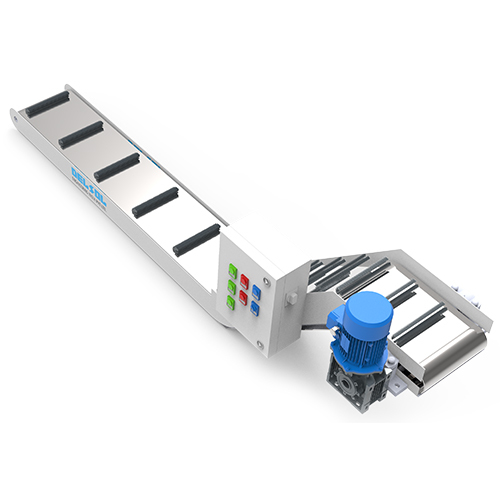

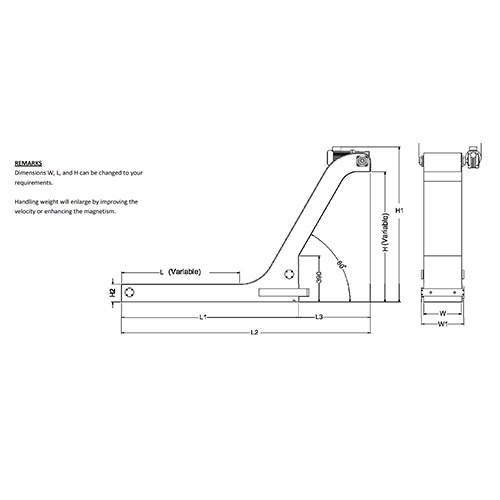

Industrial Magnetic Chip Conveyor

Price 120000 INR/ Unit

Industrial Magnetic Chip Conveyor Specification

- Power Source

- 440

- Thickness

- 3 to 5 Millimeter (mm)

- Usage

- Industrial

- Material

- MS & SS

- Height

- 500 To 1800 Millimeter (mm)

- Product Type

- Conveyor

- Weight

- 100 To 3500 Kilograms (kg)

- Color

- RAL 7035, Appel Green SS

- Length

- 1000 To 15000 Millimeter (mm)

- Width

- 600 To 1500 Millimeter (mm)

- Load Capacity

- 10 to 5000 Kilograms (kg)

- Voltage

- 440 Volt (v)

- Power

- 440 Volt (v)

- Speed

- 10 To 100 RPM

- Warranty

- 1 Years

Industrial Magnetic Chip Conveyor Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 50 Units Per Month

- Delivery Time

- 2 Week

- Main Domestic Market

- All India

About Industrial Magnetic Chip Conveyor

What is a Magnetic Chip Conveyor?

A Magnetic Chip Conveyor is an industrial material handling system designed to convey ferrous metal chips, fines, or small particles from machine tools using magnetic force. It's ideal for CNC machines, drilling, milling, and other metalworking operations.

How It Works

- Ferrous chips fall onto the conveyor bed.

- Powerful permanent magnets mounted on a moving chain attract chips through a stainless-steel cover.

- Chips travel to the discharge end as the magnets rotate.

- Chips are dropped off into a bin or central collection point.

Note: No contact between chips and moving magnets ensures clean and leak-proof operation.

Construction and Key Parts

| Component | Material / Type |

| Conveyor Bed | MS/SS with leak-proof housing |

| Magnetic Chain | High-grade Neodymium magnets |

| Cover Plate | Stainless Steel (non-magnetic) |

| Drive System | Geared Motor with sprocket drive |

| Scraper / Wiper | Optional for cleaning fine dust |

| Frame / Legs | Fabricated steel or custom height |

Technical Specifications (Sample)

| Parameter | Value |

| Conveyor Width | 150 mm to 1000 mm |

| Chip Type | Ferrous (dry or wet) |

| Inclination Angle | 0 to 75 |

| Magnetic Strength | Up to 12000 Gauss (customizable) |

| Motor Power | 0.5 HP to 2 HP |

| Discharge Height | 200 mm to 2000 mm |

| Speed | 1 to 5 m/min |

Types of Magnetic Chip Conveyors

Straight Horizontal

- For machines with low height discharge

- Compact design

Inclined Type

- L-shaped or Z-shaped

- Lifts chips to a bin or trolley

Centralized Magnetic Conveyor

- Multiple machines connected to one conveyor line

Applications

- CNC Turning Centers

- Machining Centers

- Grinding Machines

- Boring & Drilling Machines

- Gear Hobbing / Spline Rolling

- ïHandles fine ferrous chips

- ïNo jamming or chain exposure

- ïContinuous operation

- ïIdeal for wet machining

- ïLow maintenance

- ïClean coolant return

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese