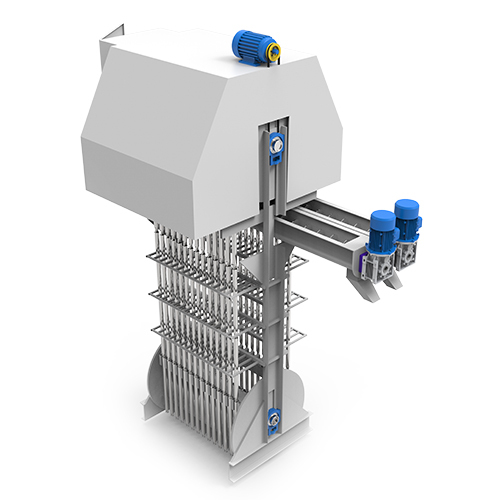

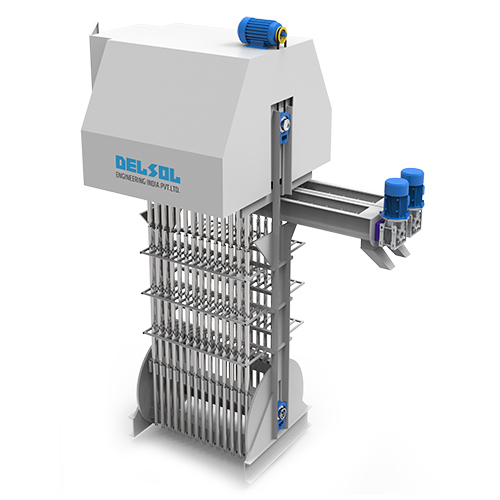

Vertical Type Candle Magnetic Separator

Price 750000 INR/ Unit

Vertical Type Candle Magnetic Separator Specification

- Power Supply

- 3 Phase

- Frequency

- 50 Hertz (HZ)

- Voltage

- 440 Volt (v)

- Composite

- Vertical Type Candle Magnetic Separator

- Power

- 440 Volt (v)

- Application

- Filter ferrous particles from coolants (e.g., rolling mills coolant oil, water-soluble coolant, or emulsions

- Weight

- 250 To 3000 Kilograms (kg)

- Color

- RAL 7035, Gray, Appel Green.

Vertical Type Candle Magnetic Separator Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 18 Units Per Year

- Delivery Time

- 20 Days

- Sample Available

- No

- Main Export Market(s)

- Asia, Australia

- Main Domestic Market

- All India

About Vertical Type Candle Magnetic Separator

PURPOSE & APPLICATION

The Vertical Candle Magnetic Separator is designed to:

- Filter ferrous particles from coolants (e.g., rolling mills coolant oil, water-soluble coolant, or emulsions).

- Maintain coolant cleanliness to improve the surface finish and tool life.

- Be used in steel cold rolling mills, grinding machines, finishing lines, pickling lines, etc.

WORKING PRINCIPLE

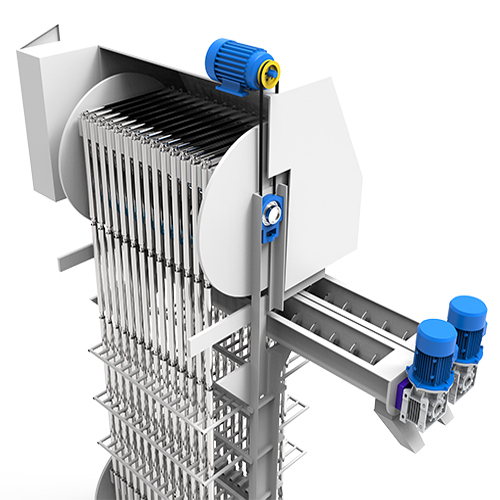

- Coolant containing ferrous impurities flows around a bundle of magnetized candle-type rods.

- The high-intensity magnetic field attracts and holds micron-sized iron/steel particles on the candle surface.

- Once saturated, the system enters a cleaning phase:

- The magnetic field is turned OFF.

- A backflush or scraping system removes the accumulated particles.

- The debris is flushed to a sludge tank or basket.

- Candles are re-magnetized and filtration resumes.

CONSTRUCTION DETAILS

| Component | Material / Description |

| Housing Tank | Mild Steel / SS304 or SS316 (optional) |

| Magnetic Candles | SS tubes with Rare Earth Magnets (NdFeB), arranged vertically) |

| Cleaning Mechanism | Pneumatic scrapers or backflush system |

| Inlet/Outlet Nozzles | Flanged or threaded (as per requirement) |

| Sludge Collection | Manual or auto-discharge system (basket/tray) |

| Drive Mechanism | Pneumatic/Hydraulic/Electric (for auto systems) |

TECHNICAL SPECIFICATIONS (Typical)

| Parameter | Value / Range |

| Flow Capacity | 50 to 2000 LPM (customizable) |

| Filtration Efficiency | Up to 10 microns |

| Magnetic Strength | 6000 to 12000 Gauss |

| No. of Magnetic Candles | Depending on flow |

| Working Temperature | 0C to 80C (higher on request) |

| Pressure Rating | 1 to 4 bar (higher optional) |

| Cleaning Frequency | Manual: Daily / Auto: Timed |

INDUSTRIAL APPLICATIONS

- Cold Rolling Mills

- Surface Grinding & Honing

- Tube/Pipe Mills

- Bearing Manufacturing

- Machining Centers (High-Precision)

- Pickling Line Coolant Tanks

ADVANTAGES

- High Filtration Efficiency " captures ultra-fine ferrous contaminants.

- Compact Vertical Design " space-saving installation.

- Continuous Operation " with minimal downtime.

- Low Maintenance " especially in automatic models.

- Improves Coolant Life " and product surface quality.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese