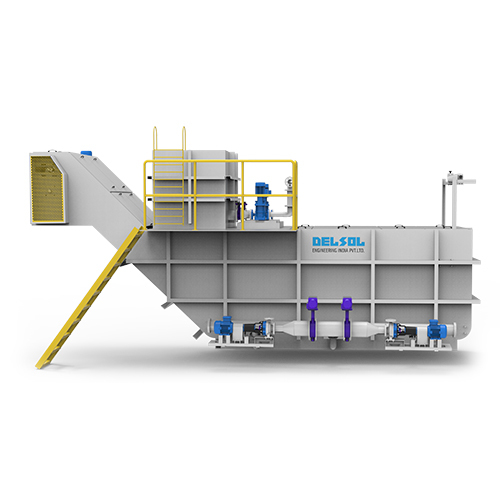

Vacuum Filter

Price 750000 INR/ Unit

MOQ : 1 Unit

Vacuum Filter Specification

- Usage

- Industrial Oil Filtration

- Material

- Other

- Processing Type

- Customized

- Height

- 1200 To 3600 Millimeter (mm)

- Condition

- New

- Technology

- Other

- Product Type

- Vacuum Filter

- Weight

- 1500 To 9000 Kilograms (kg)

- Color

- RAL 7035, Gray, Appel Green

- Power Mode

- Electric

- Length

- 1000 To 12000 Millimeter (mm)

- Voltage

- 440 Volt (v)

- Width

- 300 To 2200 Millimeter (mm)

- Power Consumption

- 440 Volt (V)

- Application

- Industrial Oil Filtration

- Warranty

- 1 Years

Vacuum Filter Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 24 Units Per Year

- Delivery Time

- 15 Days

- Main Domestic Market

- All India

About Vacuum Filter

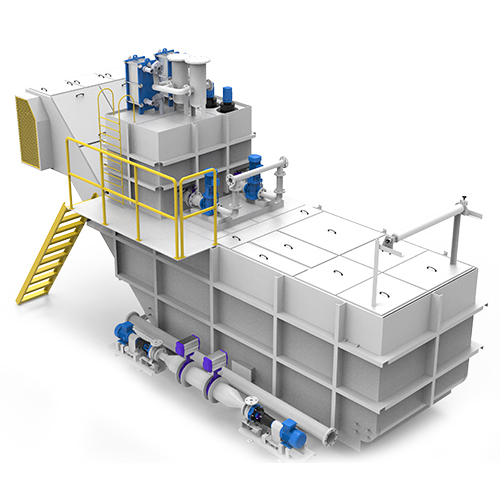

What is a Vacuum Filter?

A Vacuum Filter is a high-efficiency continuous filtration system that uses a vacuum (suction) to pull liquid through a filter media. It is ideal for fine particle filtration, particularly in grinding operations, where superior coolant clarity is required.

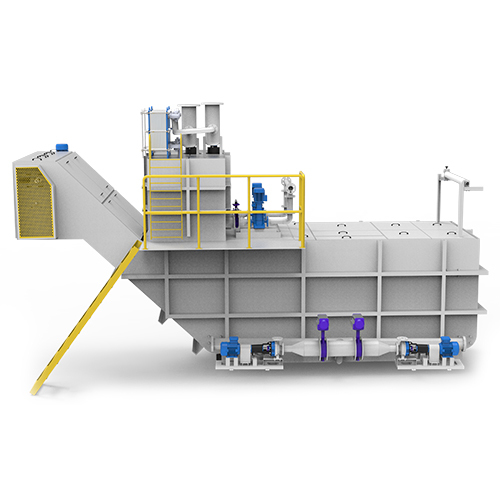

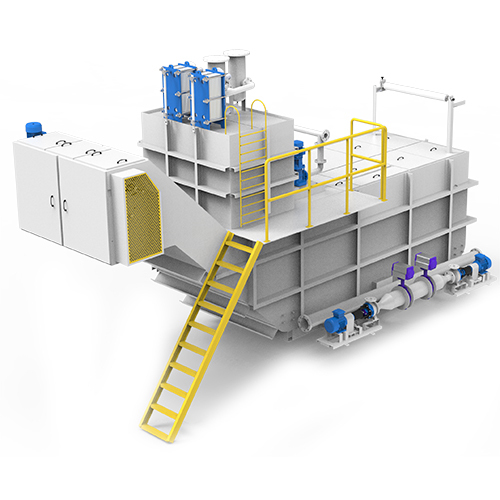

CONSTRUCTION & WORKING

Main Components:

- Dirty Liquid Inlet Tank

- Vacuum Chamber (negative pressure zone)

- Filter Media Conveyor (paper/cloth)

- Clean Tank with Coolant Pump

- Vacuum Pump

- Float Switches & Sensors

Working Principle:

- Coolant with chips enters the dirty tank.

- It is drawn through the filter media into the clean tank under vacuum pressure.

- Solids stay on the media, clean fluid passes through.

- Clogged media triggers auto-indexing mechanism (media roll moves forward).

- Spent media is collected in a waste bin.

TECHNICAL SPECIFICATIONS (Typical Ranges)

| Parameter | Range |

| Flow Rate Capacity | 100 " 3000 LPM |

| Filtration Accuracy | Up to 10 microns |

| Filter Media | Non-woven paper or fabric |

| Power Supply | 3-phase, 415V |

| Vacuum Pressure | Up to -600 mmHg |

| Construction | MS / SS 304 / SS 316 |

APPLICATIONS

- CNC grinding machines

- Surface/cylindrical/centerless grinders

- Lapping, polishing, and honing machines

- High-precision machining lines

- Washing stations requiring fine filtration

ADVANTAGES

- Excellent filtration efficiency

- Removes very fine particles (down to 10 microns)

- Fully automatic operation

- High coolant clarity for precision tools

- Customizable size & capacity

- Better tool life and surface finish

ADVANCED OPTIONS

- Pre-separation tanks

- Magnetic separator (add-on for ferrous particles)

- Vacuum pump protection filter

- Sludge compactors or cake discharge

- HMI/PLC automation system

- SS 316 for corrosive fluids

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese