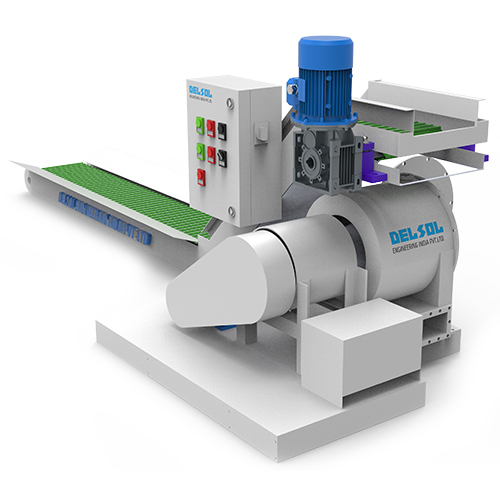

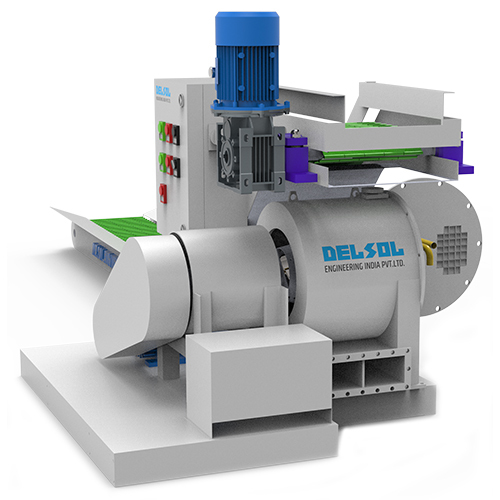

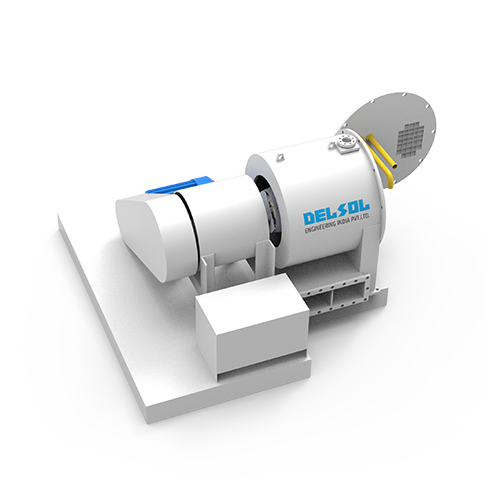

Chip Wringer

Price 150000 INR/ Unit

Chip Wringer Specification

- Temperature

- 40 Celsius (oC)

- Power Consumption

- 440 Volt (V)

- Power

- 440 Volt (v)

- Material

- Stainless Steel

- Voltage

- 440 Volt (v)

- Height

- 900 To 1500 Millimeter (mm)

- Product Type

- Chip Wringer

- Weight

- 150 To 750 Kilograms (kg)

- Color

- RAL 7035, Appel Green

- Length

- 12000 Millimeter (mm)

- Width

- 1000 To 1550 Millimeter (mm)

- Warranty

- 12 months

Chip Wringer Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 15 Days

- Main Domestic Market

- All India

About Chip Wringer

WHAT IS A CHIP WRINGER?

A Chip Wringer (also known as a Centrifugal Chip Dryer) is a mechanical separation machine that uses centrifugal force to remove residual oil or coolant from metal machining chips. It helps in recovering expensive oils, reducing disposal weight, and making chips recyclable and dry for further processing.

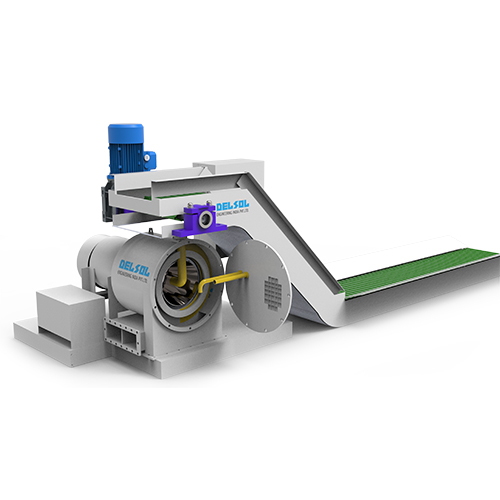

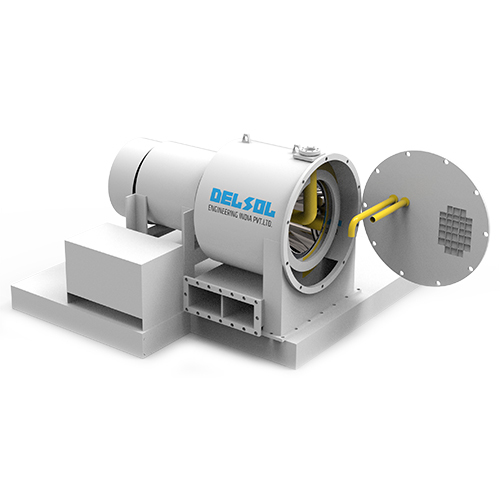

WORKING PRINCIPLE

- Wet metal chips (steel, aluminium, brass, etc.) are fed into the rotating basket of the wringer.

- A high-speed rotating drum generates centrifugal force.

- Oil/coolant is thrown outward and collected through drain outlets.

- The dry chips remain inside the basket and are discharged or manually removed.

- Oil/coolant is collected and reused or stored.

TYPES OF CHIP WRINGERS

| Type | Description |

| Manual Loading | Operator feeds and unloads chips manually |

| Auto Loading with Hopper | Automated feeding via screw or conveyor |

| Tilting Type | Basket tilts for easy unloading |

| Fixed Basket Type | Simple, rugged design for batch operation |

| Continuous Type | For high-volume chip wringing systems |

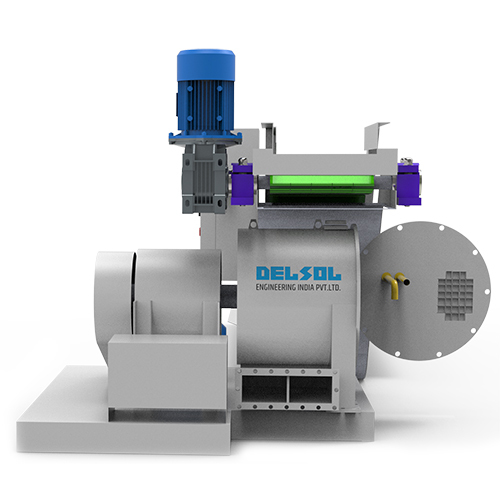

KEY TECHNICAL FEATURES

| Parameter | Typical Range |

| Capacity | 30 - 500 kg/hour |

| Basket Diameter | 300 -800 mm |

| RPM | 900 - 1800 RPM |

| Oil Recovery Efficiency | Up to 95% |

| Motor Power | 2 HP to 7.5 HP |

| Basket Material | SS perforated sheet (SS304/316) |

| Body Material | MS with powder coating or SS |

| Operation Type | Manual / Semi-automatic / PLC-based |

APPLICATIONS

Metalworking & Machining:

- CNC, VMC, and lathe shops

- Aluminium, steel, brass chip recovery

- Coolant oil reclamation

Industrial Sectors:

- Automotive parts manufacturers

- Aerospace component machining

- Heavy fabrication shops

ïEnvironmental:

- Reduces oil loss and improves recycling

- Lowers chip disposal costs (dry weight)

ADVANTAGES

- High oil/coolant recovery efficiency

- Reduces disposal cost and chip weight

- Chips are dry and reusable

- Less messy than manual draining

- Recovers expensive cutting oils

- Short payback period

SELECTION CHECKLIST

| Selection Criteria | Notes |

| Type of Chips | Steel, aluminium, brass, mixed |

| Chip Moisture | Oil-based, coolant-based, water |

| Required Output Capacity | Kg/hr or chips per batch |

| Operation Type | Manual, semi-automatic, fully automatic |

| Recovery Requirement | % of oil/coolant recovery needed |

| Available Space & Power | Floor footprint and electrical load |

| Maintenance Access | Should be easy to clean and service |

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese