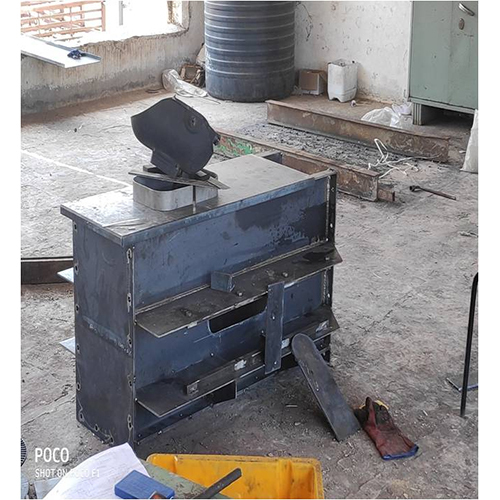

MS Bucket Elevator

Price 50000 INR/ Unit

MS Bucket Elevator Specification

- Structure

- Chain Conveyor

- Frame Material

- Mild steel

- Load Capacity

- Varies based on model and design Tonne

- Lifting Height

- Adjustable as per requirement Foot (ft)

- Size

- Different available

- Weight

- 100 To 10000 Kilograms (kg)

- Voltage

- 440 Volt (v)

- Working Temperature

- 30 To 60 Celsius (oC)

- Application

- Industrial

MS Bucket Elevator Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 30 Days

- Main Domestic Market

- All India

About MS Bucket Elevator

What is a BucketElevator?

A Bucket Elevator is a vertical or inclined conveyorsystem that uses a series of buckets mounted on a belt or chain to liftbulk materials continuously. It is used where vertical material handling isrequired with high throughput.

Working Principle

- Buckets are attached to a belt or chain.

- The drive unit rotates the belt/chain.

- Buckets scoop the material at the boot (bottom).

- Material is elevated vertically.

- Buckets are tipped or rotated at the top (discharge) to empty the material.

- Buckets return empty to the loading area.

Main Components

| Component | Description |

| Head Section | Housing for drive shaft, pulley/sprocket, and discharge chute |

| Boot Section | Loading zone with inlet hopper and tensioning system |

| Casing | Enclosed structure for belt/chain & buckets |

| Buckets | Carry the material; metal or plastic |

| Belt or Chain | Drives the buckets (rubber belt / steel chain) |

| Drive Motor & Gearbox | Powers the system |

| Bearings & Shaft | Support the pulleys/sprockets |

Types of Bucket Elevators

| Type | Description | Application |

| Centrifugal Discharge | Fast speed; material flung out | Granular materials (grains, pellets) |

| Continuous Discharge | Slower speed, material slides | Fragile, sticky, or abrasive materials |

| Positive Discharge | Buckets inverted mechanically | Inclined elevators |

| Z-type / U-type | Horizontal + vertical transfer | Food & packaging industry |

| Chain Type | Heavy-duty, high-temp | Cement, minerals, ash |

Materials ofConstruction

| Component | Material |

| Buckets | Mild Steel, Stainless Steel, Plastic (HDPE/PP/PU) |

| Belt | Rubber, PVC, Food-grade PU |

| Chain | Hardened Steel, SS |

| Structure | MS (IS 2062), SS304/316 for food/pharma |

| Bearings | SKF/NTN/FAG type |

TechnicalSpecifications (Typical Range)

| Parameter | Range |

| Capacity | 1 500 TPH |

| Lift Height | Up to 60 meters |

| Bucket Width | 150 mm 1000 mm |

| Bucket Pitch | 200 mm 400 mm |

| Belt Speed | 0.5 2.5 m/s |

| Power Rating | 1 50 HP |

| Discharge Type | Centrifugal / Gravity |

| Loading Type | Manual / Screw-fed / Belt-fed |

Design Codes & Standards

- CEMA Standard No. 375 Bucket Elevator Book

- IS 7167 Code of practice for bucket elevators

- DIN 15251, 15234

- ISO 9001:2015 certified designs

- FEM & Structural FEA for load-bearing

Advantages

- Vertical lift saves floor space

- High throughput

- Fully enclosed dust-free

- Minimal spillage and product loss

- Durable and low maintenance

- Available in hygienic (SS) models

Limitations

- Not suitable for wet, sticky materials (unless custom)

- Limited to vertical or steep incline only

- Bucket wear over time

- Needs proper alignment & tensioning

Applications

- Grain & Agriculture Wheat, corn, soy

- Food & Pharma Sugar, flour, tablets

- Cement & Building Materials Lime, sand, cement

- Power Plants Fly ash, coal

- Chemical Industry Granules, flakes

- Plastic Industry Resin pellets

- Foundry & Mining Sand, ore

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese