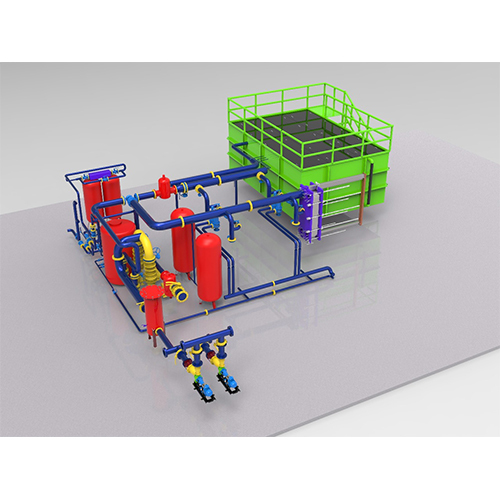

Oil & Gas Lubricant Pipeline

Price 35000 INR/ Unit

Oil & Gas Lubricant Pipeline Specification

- Application

- Oil & Gas Industri

- Surface Finish

- Blasting & Painting

- Dimension (L*W*H)

- 1 Meter (m)

- Pressure Ratings

- 2.5 Bar To 20 Bar

- Fittings

- Elbows, Tees, Reducers, Couplings, Flanges, Caps Nipples, Valves

- Working Presssure

- 2.5 Bar To 20 Bar

- Capacity

- 10 To 10000 Ltr/hr

- Diameter

- 25 To 500 Millimeter (mm)

- Usage

- Industrial

- Material Grade

- MS & SS

- Material

- MS & SS

- Pipe Type

- Seamless pipes & ERW pipes

Oil & Gas Lubricant Pipeline Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 500 Units Per Month

- Delivery Time

- 1 Months

- Main Domestic Market

- All India

About Oil & Gas Lubricant Pipeline

What is a Gas Pipeline?

A Gas Pipeline is an interconnected system of pipesdesigned to transport natural gas, LPG, biogas, or industrial gases fromone location to another such as from refineries to distribution points, orfrom mainlines to end-users like homes, factories, or power plants.

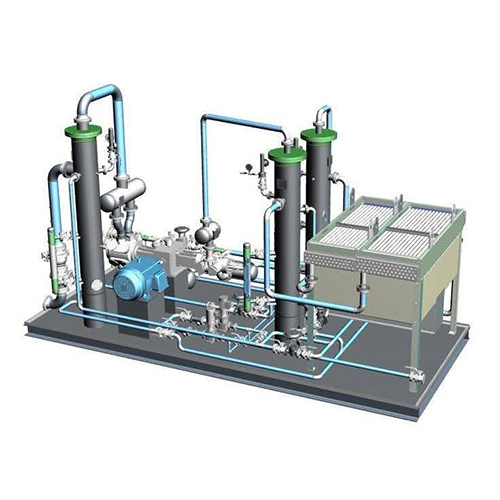

Working Principle

- Pressurized gas flows through pipes under controlled conditions.

- A compressor or pressure regulator maintains flow pressure.

- Valves regulate flow, isolate sections, or vent pressure.

- Monitoring systems ensure leak-free, safe, and efficient delivery.

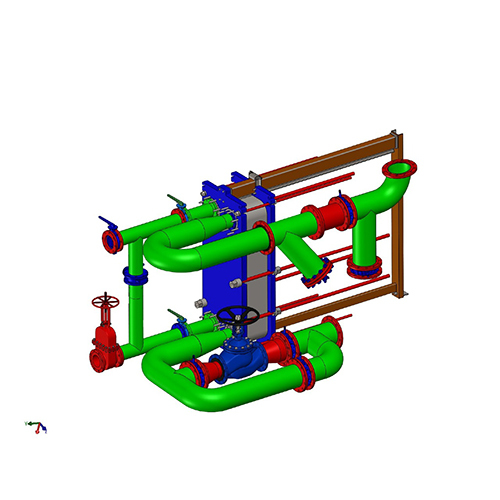

Key Components

| Component | Description |

| Pipes | Seamless or welded, carbon/SS/HDPE |

| Fittings | Elbows, reducers, tees, couplings |

| Valves | Ball, gate, pressure relief, solenoid |

| Flanges | For jointing and maintenance |

| Regulators | Control pressure at outlets |

| Flow Meters | Measure gas flow (cubic meters/hour) |

| Filters/Strainers | Remove impurities |

| Gas Detectors | Detect leaks for safety |

| Control Panel | Automation and monitoring |

Types of GasPipelines

| Type | Description | Use |

| Transmission Pipeline | Large diameter, long distance | City-wide gas distribution |

| Distribution Pipeline | Medium pressure, shorter length | Industrial, residential use |

| Service Line | Final connection to building | Homes, hotels, labs |

| Underground Pipeline | Buried for safety and space | Most common type |

| Above-Ground Pipeline | Exposed for access | Industrial plants |

| Flexible Gas Pipe (CSST) | For appliances | Domestic kitchens, HVAC |

Materials Used

| Material | Typical Use |

| Carbon Steel (ASTM A106, API 5L) | High-pressure, long-distance |

| Stainless Steel (SS304, SS316) | Corrosive gas, cleanroom |

| Copper | Domestic gas lines |

| HDPE (PE-100) | Low pressure, buried line |

| GI (Galvanized Iron) | Old style; now phased out in many places |

TechnicalSpecifications (Typical Range)

| Parameter | Value |

| Pipe Diameter | 48 |

| Pressure Rating | 2 bar to 100 bar |

| Temperature Range | -20C to +200C |

| Flow Capacity | 10 10,000 Nm/hr |

| Design Life | 2050 years |

| Coating (underground) | 3LPE / Bitumen / HDPE |

| Joints | Butt weld / Threaded / Flanged / Fusion |

Design Standards& Codes

- ASME B31.3 Process Piping

- ASME B31.8 Gas Transmission & Distribution

- API 5L Pipe standards for line pipe

- IS 6044 LPG installation in buildings

- NFPA 54 National Fuel Gas Code

- OISD Guidelines (India)

- PNGRB Guidelines (India)

Advantages

- Safe and reliable gas transportation

- High efficiency and low operating cost

- Underground pipelines save space

- Suitable for remote areas

- Durable materials last for decades

SafetyConsiderations

- Pressure Relief Valves

- Flame Arrestors

- Gas Leak Detectors

- Cathodic Protection (for corrosion)

- Color Coding (yellow for natural gas)

- Firefighting provisions

- Emergency Shutdown System (ESD)

Applications

- Residential Gas Supply Kitchens, water heaters

- Commercial Use Hotels, hospitals, malls

- Industrial Boilers, furnaces, heat treatment

- CNG/PNG stations

- Power Plants

- Chemical & Pharma Industry

- Biogas Pipelines Renewable energy sector

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

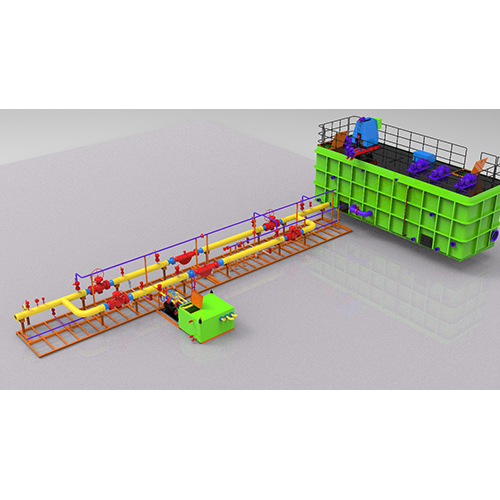

More Products in Chemical Plants Pipeline Category

Industrial Chemical Oil and Gas Plants Pipeline

Price 100000 INR / Unit

Minimum Order Quantity : 1 Plant

Corrosion Resistant : Yes

Features : High Quality

Surface Finish : Paint Coated

Application : Oil & Gas Industri

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese