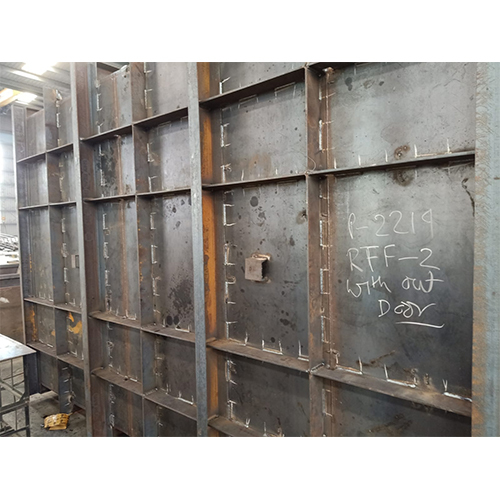

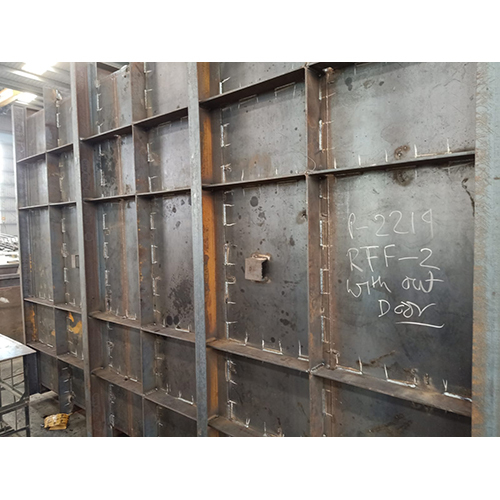

Furnace Casing

Price 50000 INR/ Unit

Furnace Casing Specification

- Condition

- New

- Usage

- Heat Treatment furnace

- Power

- 440 Volt (v)

- Height

- 1000 To 2200 Millimeter (mm)

- Voltage

- 440 Volt (v)

- Product Type

- Furnace Casing

- Weight

- 300 To 30000 Kilograms (kg)

- Color

- RAL 7035, Black, Appel Green

- Length

- 1000 To 2000 Millimeter (mm)

- Width

- 600 To 1500 Millimeter (mm)

- Warranty

- 1 years

Furnace Casing Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 50 Units Per Month

- Delivery Time

- 1 Months

- Main Domestic Market

- All India

About Furnace Casing

What is FurnaceCasting?

Furnace Casting refers to the melting of metals ina furnace and pouring the molten metal into molds to form a desiredshape (castings). This process is widely used in foundries for producing partsin steel, iron, aluminum, copper alloys, etc.

Core Concept

- Metal is melted in a furnace (induction, electric arc, cupola, etc.).

- Molten metal is poured into a pre-made mold (sand, ceramic, metal die).

- The casting is allowed to solidify.

- The mold is removed to extract the cast component.

- Casting is cleaned, machined, or heat-treated as needed.

Types of FurnaceUsed for Casting

| Furnace Type | Fuel Source | Common Uses |

| Induction Furnace | Electric | Steel, stainless steel, copper |

| Electric Arc Furnace (EAF) | Electric arc | Steel scrap melting |

| Cupola Furnace | Coke | Cast iron |

| Crucible Furnace | Gas, oil, electric | Small batch melting (aluminum, bronze) |

| Rotary Furnace | Oil/gas fired rotating chamber | Lead, aluminum |

| Reverberatory Furnace | Gas-fired | Non-ferrous bulk alloys |

Materials CommonlyCast

- Ferrous:

- Grey Cast Iron

- SG Iron (Ductile Iron)

- Mild Steel / Alloy Steel / Stainless Steel

- Non-Ferrous:

- Aluminum alloys

- Copper / Bronze

- Zinc

- Magnesium

Casting ProcessFlow (Typical)

- Pattern Making

- Mold Preparation (green sand, shell mold, investment)

- Melting in Furnace

- Pouring molten metal

- Cooling and Solidification

- Shakeout and Mold Removal

- Fettling and Finishing

- Inspection and Testing

TechnicalSpecifications (Typical Range)

| Parameter | Range |

| Casting Weight | 0.1 kg to 5000 kg |

| Tolerance | 1 mm to 5 mm (based on process) |

| Surface Finish | 3.2 m 25 m (Ra) |

| Pouring Temp | 650C (Al) to 1600C (Steel) |

| Casting Methods | Sand / Die / Investment / Shell Mold |

| Core Use | Yes (for internal cavities) |

Relevant Design& Quality Standards

- ASTM A48 / A536 For iron castings

- IS 210 / IS 1865 Indian standards for CI and SG Iron

- EN 1561 / 1563 European standards

- ASME / ANSI For pressure-retaining castings

- ISO 8062 Dimensional tolerances for castings

- NDT: UT, RT, MPI, DPI for defect detection

Advantages

- Complex shapes in a single pour

- Cost-effective for large production

- Wide range of sizes and materials

- Good mechanical properties with alloys

- Suitable for both ferrous and non-ferrous metals

Limitations

- Shrinkage and porosity issues

- Requires pattern and mold setup

- Surface finish may require post-processing

- Limited precision vs machining

Applications

- Automotive Engine blocks, manifolds, gear housings

- Power Plants Turbine components, burner nozzles

- Pumps & Valves Casings, impellers, covers

- Heavy Equipment Frames, counterweights

- Agriculture Equipment

- Mining & Earthmoving

- Railway & Defense

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Furnace Casing Category

Furnace Casing and Ducting

Price 50000 INR / Unit

Minimum Order Quantity : 1 Unit

Size : As per buyer's requirement

Condition : New

Product Type : Furnace Casing

Color : Grey

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese