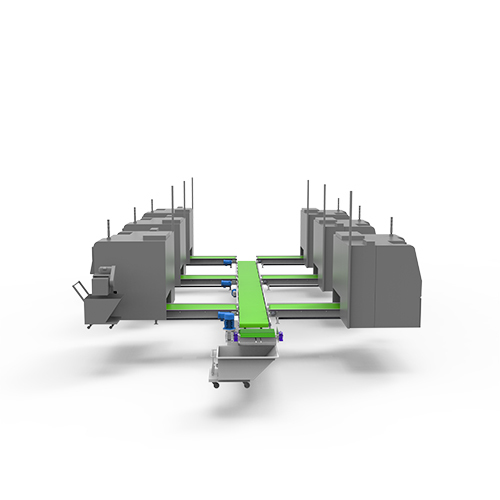

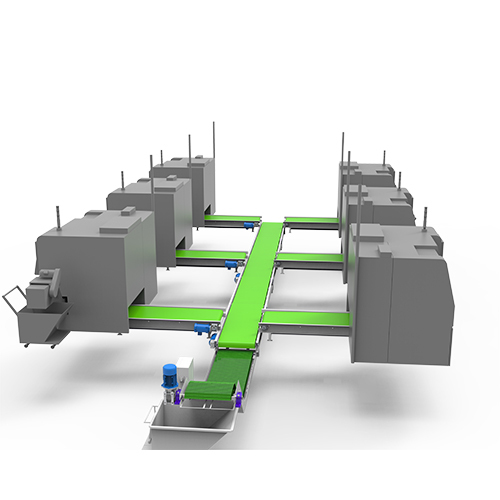

CENTRALIZE CONVEYOR SYSTEM

Price 125000 INR/ Unit

CENTRALIZE CONVEYOR SYSTEM Specification

- Thickness

- 3 to 5 Millimeter (mm)

- Power Source

- 440

- Usage

- Industrial

- Material

- MS & SS

- Height

- 300 To 3600 Millimeter (mm)

- Product Type

- Conveyor

- Weight

- 150 To 2200 Kilograms (kg)

- Color

- RAL 7035, Black, Appel Green

- Length

- 1000 To 15000 Millimeter (mm)

- Width

- 300 To 1500 Millimeter (mm)

- Load Capacity

- 10 to 5000 Kilograms (kg)

- Voltage

- 440 Volt (v)

- Power

- 440 Volt (v)

- Speed

- 10 To 100 RPM

- Warranty

- 1 Years

CENTRALIZE CONVEYOR SYSTEM Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 30 Units Per Month

- Delivery Time

- 1 Week

- Main Domestic Market

- All India

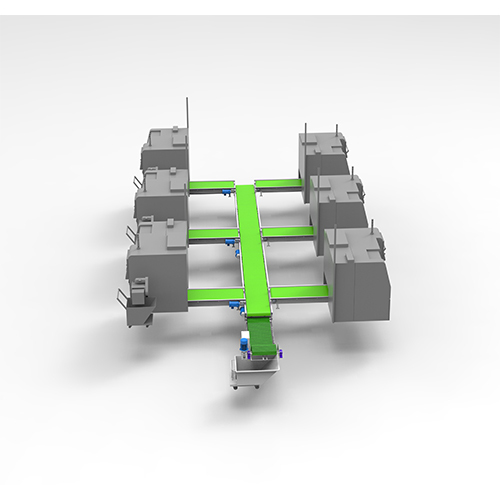

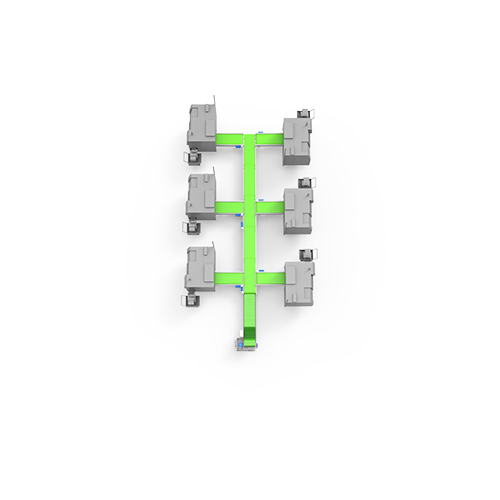

About CENTRALIZE CONVEYOR SYSTEM

CENTRALIZECONVEYER SYSTEM!

Centralized Chip ConveyorSystem

Overview:

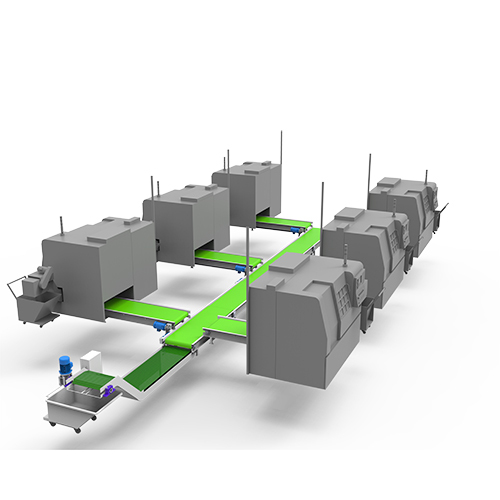

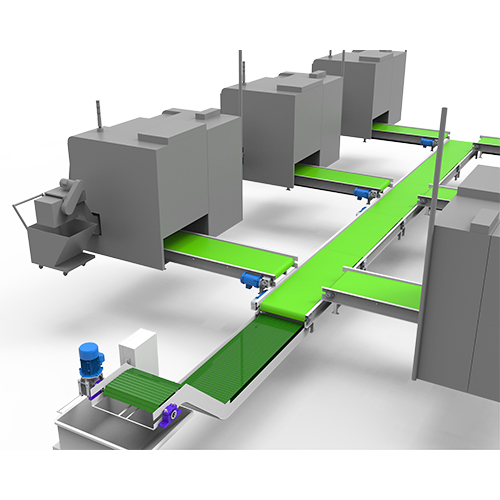

A Centralized Chip ConveyorSystem is an integrated material handling system used to collect,transport, and manage metal chips from multiple machine tools to a centralizeddisposal or recycling point. This system improves shop floor cleanliness,automation, and chip handling efficiency in CNC and machining environments.

Technical Specifications:

| Parameter | Description |

| Application | Chip handling in CNC, VMC, HMC shops |

| Material Handled | Steel, Aluminum, Brass, Cast Iron Chips |

| Chip Type | Dry / Wet / Stringy / Fine / Coarse |

| Conveyor Types Used | Scraper, Slat, Screw, Belt, Magnetic, or Combination |

| Collection Points | From multiple machines |

| Disposal Point | Briquetting machine / Chip wringer / Scrap bin |

| Control | Centralized PLC / Electrical Panel |

| Customization | Layout, capacity, and design tailored to shop floor |

| Power Supply | 3 Phase, 415V, 50Hz or as required |

| Material | Mild Steel / SS304 (as required) |

|

|

|

Advantages:

- Reduces manpower and manual chip handling

- Improves floor cleanliness and machine uptime

- Efficient centralized chip disposal

- Saves space and improves shop organization

- Integrates easily with chip wringers, oil skimmers, and coolant filtration systems

- Automatable with sensors and level indicators

Applications:

- Automotive Component Manufacturers

- CNC and VMC Machining Centers

- Die and Mold Manufacturers

- Foundries and Fabrication Units

- Aerospace & Defense Workshops

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in CONVEYER SYSTEM Category

Material Handling Conveyor System

Price 50000 INR / Vial

Minimum Order Quantity : 1 Unit

Power : 440 Volt (v)

Type : Incline and Decline Conveyor

Load Capacity : 10Kg to 1 Tone Tonne

Voltage : 440 Volt (v)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese